Counterfeit Mitigation

The ongoing need for obsolete devices to support legacy systems and equipment without costly redesigns is complicated by the threat of counterfeit and otherwise substandard electronic components in the supply chain. Before a component lacking traceability to its OCM is utilized (especially in a military or aerospace application), the smart (and usually required) approach is to mitigate the risk associated with such parts by careful sourcing, inspection and testing to AS6081, DFARS Part 252.246-7007 or the appropriate standard.

Zero Tolerance for Counterfeit Product:

- One of the first to develop a formal inspection procedure, CAPP, prior to the development of industry standards

- All components are sourced via a scrubbed vendor list

- Inspection and testing in accordance with applicable standards for quality and authenticity (including flowdown, MilSpec and aerospace)

- Affiliation with a highly-credentialed independent test house ensures integrity of advanced inspection and testing

- Every inspector is certified to AS6081 counterfeit component detection methods

Adherence to appropriate standards or flowdown requirements may include:

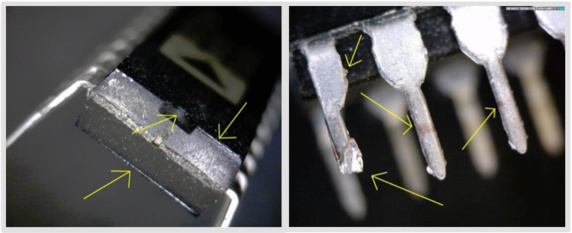

- External Visual & Dimensional Inspection

- Marking Permanency & Blacktop Inspection

- X-Ray Die Bond & Frame Inspection

- XRF Spectrum & SEM Analysis

- Group A Electrical Testing at Temperature

- Decapsulation/delidding

- Destructive Physical Analysis (DPA)

- OCM Die Database Comparison

Basic CAPP/CAVR-level inspection is available for commercial applications.

For a more complete description of our Component Authenticity Services see this Counterfeit Avoidance Overview.

Certified to

Certified toAS6081 Methods